| GaugeType | B-A Gauge |

|---|---|

| Pressure Range | |

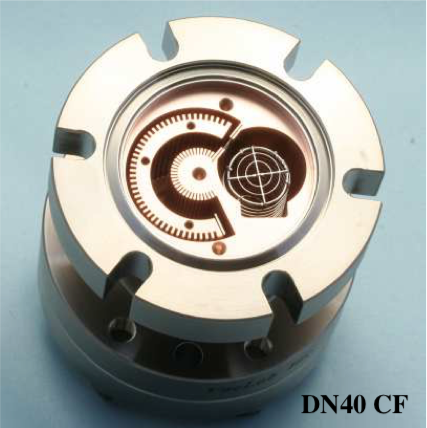

| Flange | DN40CF |

Measurable as low as 10-12Pa (10-14mbar)

♦ Reduction of soft X-ray & ESD by Bent Belt-Beam method.

♦ Full-closed cylindrical cage-grid with an axial-slit.

♦ Low outgassing hot-cathode gauge by using 0.2% BeCu alloy body.

Operational parameters & data

Electron energy: 120eV (standard)

Filament potential: 100V (standard)

Filament power: 2V×1.5A at 1.6mA

Deflector bias = 155V (between 1~4mA)

Degas: Electron bombardment (450V×10~45mA)

Bakeout temperature: 280°C max without cable

Size: CF40 ( 1.1kg)

Connector: BNC & 8 pin burndy-j

Sensitivity factor: 5~8×10-2Pa-1 (at 1~4mA)

X –ray limit < 5 x 10-12 Pa

3BG can operate with Prevac MG13/14/15 or Leybold IM540

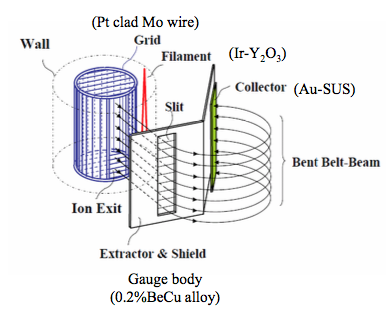

What is Bent Belt-Beam (BBB) gauge ?

3BG is a commercially extreme-high vacuum hot-cathode ionization gauge head that can measure pressure as low as 5.4 X 10-12Pa, by reducing the limit imposed by soft x-rays, electron- stimulated desorption (ESD), and outgassing.

The gauge construction includes a cylindrical grid, which is close at both ends; ions are drawn from the grid through a long, axial slit made in the cylindrical surface.Thus, the ion beam that emerges forms a “belt”.This belt-like ion beam is guided on a terminates on a plate collector arranged after a beam trajectory rotation of 240°. These elements are embedded in a solid cylinder of 0.2% BeCu alloy, which has a low emissivity (radiation factor) and high thermal conductivity. As a result, the effects of heat radiation and outgassing (caused by the hot-cathode filament) and soft x- ray photoemission(the grid is the soft x-ray source) are reduced in the deflector/collector region. This electrode arrangement can also greatly decrease the flux of soft x-rays and ESD in the direction of the belt ion beam because it sets to 90°the angle between the extracted gas-phase ion beam and the maximum flux of soft x-rays and ESD.

In addition, it achieves an extremely low pressure measurement limit by minimizing loss in the ion transport, and because the collector is well hidden, being located after the large deflection of the ion beam.

The gauge construction includes a cylindrical grid, which is close at both ends; ions are drawn from the grid through a long, axial slit made in the cylindrical surface.Thus, the ion beam that emerges forms a “belt”.This belt-like ion beam is guided on a terminates on a plate collector arranged after a beam trajectory rotation of 240°. These elements are embedded in a solid cylinder of 0.2% BeCu alloy, which has a low emissivity (radiation factor) and high thermal conductivity. As a result, the effects of heat radiation and outgassing (caused by the hot-cathode filament) and soft x- ray photoemission(the grid is the soft x-ray source) are reduced in the deflector/collector region. This electrode arrangement can also greatly decrease the flux of soft x-rays and ESD in the direction of the belt ion beam because it sets to 90°the angle between the extracted gas-phase ion beam and the maximum flux of soft x-rays and ESD.

In addition, it achieves an extremely low pressure measurement limit by minimizing loss in the ion transport, and because the collector is well hidden, being located after the large deflection of the ion beam.

3B-Gauge Head is a product of Tokyo Electronics Co., Ltd.

Part codes

| TG Part Code | TG Part Specifications | TG Part Contents |

|---|---|---|

| 3BG-03 | 3B Gauge head | 3BG Gauge head & cables |