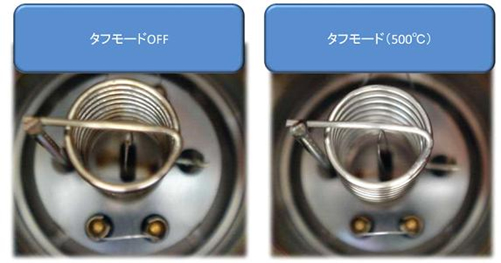

Tough gauge© is specially designed for vacuum applications where contaminants create problems for conventional Bayard-Alpert (B-A) gauges. B-A Tough gauge© heats up the grid and collector while meassuring vacuum pressure and prevent contaminants from being deposited on surfaces of the grid and the collector. These comtaninants cause short life time of gauge and inaccuracy of the pressure meassurement.

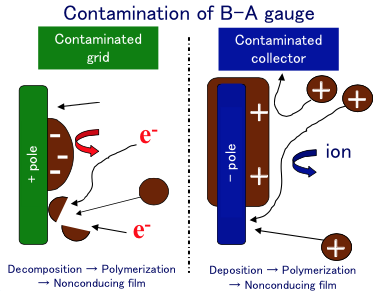

- Problems on conventional B-A gauges with pollutants.

- Contaminated grid

- Increase of emission power

- shorten the life time of filaments

- Contaminated collector

- Degrade its sensitivity

- wrong measurement of pressure

- usually measure lower than real pressure.

- Typical sources of contaminants

- Plasticiser evaporation

- -> Pthalic acid, Adipic acid

- Wires, motors and seals

- -> Siloxiane

- Metal Organic gases in Semiconductor Production machine

- -> Residual photoresist

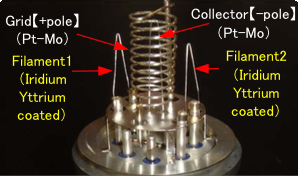

Structure of the B-A Tough Gauge©

Thermoelectron which came out of a filament goes into the Grid. (Emission Current: Ie). Thermoelectron hits a gas molecule. Then, positive ion arises and gathers for the collector. (Ion current:Ii)

* Ii = S x Ie x P (S is a sensitivity coefficient and invariable.)

Pressure can be known, if Ie is kept constant and Ii is measured.

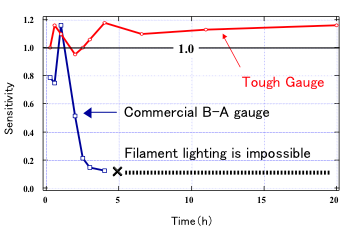

Comparison Chart:

Tough Gauge© vs Conventional B-A Gauge

Performance of the sensitivity in Siloxane.